Performing these inspections can save you time, effort, and disappointment by recognizing in advance where you need to fix your model to maintain Additive Manufacturing methods. Validate Narrow Gaps: You can monitor where characteristics such as holes and extrudes have appeared in gaps in the geometry that are too small to print perfectly.

Validate Thin Walls: This will enable you to see where your part geometry is so slim that it may break while printing or the removal of support compositions. Within the 3D Print command in Creo Parametric, users have access to two diverse sets of Print Checking that can be accomplished with exceptional functionality:

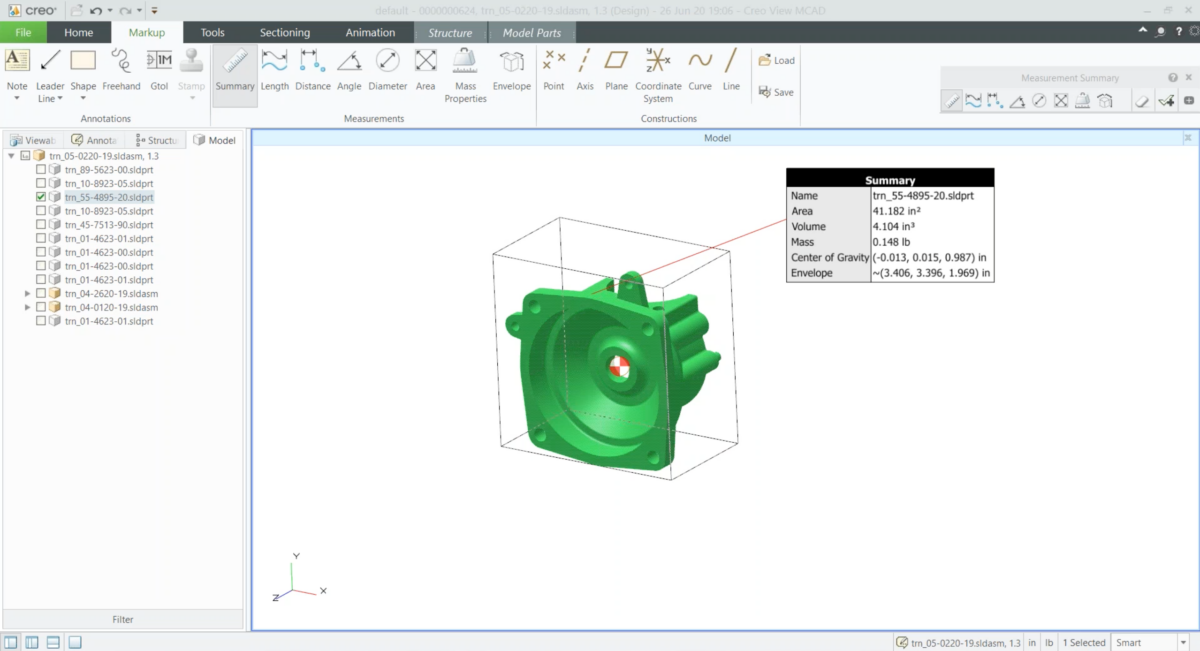

You can even demonstrate the required assistant material from the 3D Print interface. With 3D Systems combination, you can also specify materials and colors as well as determining the build and building material. Within CreoTek India’s PTC Creo choices dialog box, you can set up an attachment to these printers, as well as a generic printer or a Windows 10 printer, using a URL or IP address. Interoperability to 3D PrintersĬreoTek Systems India maintains creo parametric interoperability with a variety of plastic printers.

0 kommentar(er)

0 kommentar(er)